|

Welcome to Advanced Inspection

Technology

Home of the Visual Plus system

The only eddy current inspection device both used and recommended by

Luxfer Gas Cylinders - ensuring the same results upon cylinder return to

the manufacturer.

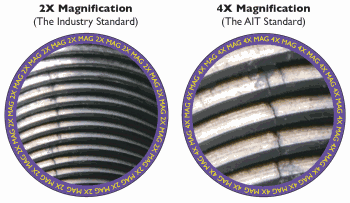

Professionally competent visual inspections are a key element in the

proper maintenance of gas cylinders (such as those used for scuba diving

and by firefighters) and the inspection of cylinder neck threads is an

important part of the process.

Even the best trained and most experienced technician can miss or

wrongly diagnose small imperfections, such as hairline cracks and folds

in the neck/shoulder area of aluminum cylinders using hydrostatic

testing alone. Visual Plus, a non destructive testing device, identifies

100% of these defective cylinders using the latest in eddy current

technology... Don't leave it to chance! Even the best trained and most experienced technician can miss or

wrongly diagnose small imperfections, such as hairline cracks and folds

in the neck/shoulder area of aluminum cylinders using hydrostatic

testing alone. Visual Plus, a non destructive testing device, identifies

100% of these defective cylinders using the latest in eddy current

technology... Don't leave it to chance! Anyone working

around aluminum high-pressure gas cylinders knows how reliable they are.

In fact, they are so dependable that often we forget they need to be

treated with care and respect. Proper maintenance is necessary to make

sure cylinders are fit for service, especially when they undergo harsh

service, such as scuba diving and firefighting.

Professionally competent visual inspections are a key element in the

proper maintenance of gas cylinders, and the inspection of cylinder neck

threads is an important part of the process. Yet even the best trained

and most experienced technician can miss or wrongly diagnose small

imperfections, such as hairline cracks and folds.

That's where Visual Plus comes in!

Visual Plus is a non-destructive testing (NDT) device which utilizes

eddy currents to detect neck and shoulder cracks, folds or other similar

imperfections in aluminum cylinders such as scuba, SCBA (all metal,

hoop-wrap or full wrap), beverage, medical, industrial gas cylinders,

fire extinguishers, etc.

An electromagnetic wave is introduced into the metal of the vessels near

the area which is desirable to inspect for imperfections (the threaded

area). The wave causes currents to flow in a circular manner in the

metal. They are called eddy currents because the flow is circular. An

imperfection can increase the path that the currents have to flow and so

make the material appear higher in

resistance

in that region where the imperfection is present. This generates a spike

on the computer generated report which alerts the technician to a

problem that requires further investigation. resistance

in that region where the imperfection is present. This generates a spike

on the computer generated report which alerts the technician to a

problem that requires further investigation.

Hydrostatic testing alone does not reveal cracking in the neck/shoulder

area of aluminum cylinders unless they are leaking. Visual Plus

identifies 100% of these defective cylinders... Don't leave it to

chance!

See a sample printout of a vessel with an imperfection in the neck by

clicking on an image on the left. |

Even the best trained and most experienced technician can miss or

wrongly diagnose small imperfections, such as hairline cracks and folds

in the neck/shoulder area of aluminum cylinders using hydrostatic

testing alone. Visual Plus, a non destructive testing device, identifies

100% of these defective cylinders using the latest in eddy current

technology... Don't leave it to chance!

Even the best trained and most experienced technician can miss or

wrongly diagnose small imperfections, such as hairline cracks and folds

in the neck/shoulder area of aluminum cylinders using hydrostatic

testing alone. Visual Plus, a non destructive testing device, identifies

100% of these defective cylinders using the latest in eddy current

technology... Don't leave it to chance!